SMARTBOX Project: Closing and Review Meeting

After a journey filled with dedication, collaboration, and remarkable achievements, we are proud to announce the official closing of the SMARTBOX project. 🎉

📸 Take a look at the vibrant faces that fuelled our discussions and collaborations during this momentous occasion!

🔍 Key Highlights:

In our recent Review Meeting with the Project Officer of CBE JU and Workpackage leaders, we reflected on our journey. The SMARTBOX project fostered a robust joint collaboration among partners, creating an open atmosphere for fruitful discussions that fueled progress and innovation in enzyme development and upscaling processes.

📊 Project Management Insights:

-

Experienced Beneficiaries: The project involved experienced beneficiaries in funding programs, ensuring a strong foundation for success.

-

Collaborative Exchange: Clear responsibilities and regular exchange between academia and industry partners fostered a huge collaboration.

-

Strong Team Dynamics: WP3 benefited from a strong team dynamic due to previous collaborations.

-

Transparency and Open Culture: An open culture for discussion points was maintained throughout, emphasizing the importance of transparency.

-

Rich in Results: The project yielded a plethora of results with significant potential for further exploitation.

-

Relevant Objectives: Achieved objectives are not only relevant to our stakeholders but also to CBE JU.

Thank you to all partners and stakeholders for your invaluable contributions to the SMARTBOX project’s success. Stay tuned for more updates on our journey and future endeavours!💡 #SMARTBOXProject #ClosingMeeting #Collaboration #Innovation

February 2024

Final Project meeting

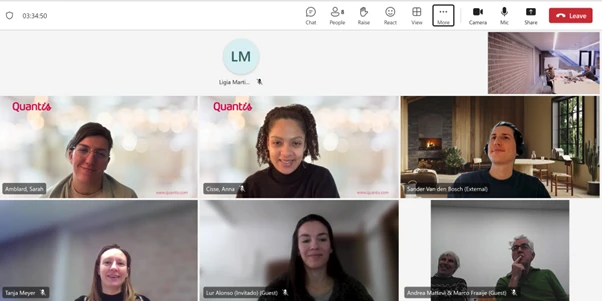

🚀 SMARTBOX’s Final Project Meeting Recap – Jan 9, 2024! 🌱

At SMARTBOX, our commitment to sustainable chemistry drives us to innovate, turning plant biomass into valuable bioaromatics and 2G sugar (polymers), shaping a greener future. 🌐✨ and further one using this feedstock for innovative technology conversion to high-end products.

📊 Meeting Highlights:

Our recent online meeting on Jan 9, 2024, marked a pivotal moment for SMARTBOX. We presented a comprehensive summary of results, discussed the impact of our project, and shared insights into the outreach achieved. The meeting also featured a crucial Workpackage leader rehearsal, preparing for the upcoming Review Meeting with the Project officer of CBE JU, and a symbolic wrap-up of this significant chapter in our sustainable chemistry venture.

📸 Snapshot from the Meeting: Check out the vibrant faces that fueled our discussion and collaboration! Thank you for being part of this impactful journey toward sustainability! Stay tuned for more updates on our innovative endeavors. 💚 #SMARTBOXProject #FinalMeetingRecap #SustainableChemistry #bio-aromatics #SnapshotFromTheMeeting

January 2024

Faces behind the exploitation of results

🎥 Step into sustainability and explore our latest videos unveiling the motivation behind SMARTBOX’s efforts and captivating content awaiting you.

🌐 Sustainability Strides: Join Tanja Meyer and Bio Base Europe Pilot Plant, essential SMARTBOX partners, as Tanja shares insights into effective project management and collaboration for a greener future. 🌱 https://www.linkedin.com/feed/update/urn:li:ugcPost:7142480415872675840/

🔬 Enzyme Engineering Unveiled: Journey with Dr. Lígia O. Martins from ITQB, unfolding the sustainable advancements in enzyme innovation. 🌱 https://www.linkedin.com/feed/update/urn:li:ugcPost:7143164024724099072/

🌿 Sustainable Chemistry Insights: Engage with Sander Van den Bosch from Biocon as he unravels the secrets of sustainable chemistry. Watch Sander’s Video SMARTBOX Project on LinkedIn: Pilot Facility for Reductive Catalytic Fractionation

🌱 Bioprocessing Innovation: Learn bioprocessing with Rakesh Nair from Bio Base Europe Pilot Plant, navigating through sustainable milestones. 💡 https://www.linkedin.com/feed/update/urn:li:ugcPost:7143553546787975168/

🌿 Innovation with B4Plastics: Explore sustainable biopolymers with Sil Nevejans from B4Plastics, shaping the future of bio-based plastics. 🌍 Watch Sil’s Video SMARTBOX Project on LinkedIn: B4Plastics explain their approach as biomaterial architecture designer.

🌐 Techno-economic Assessment: Tune in as Cedric Vander Cruyssen from Bio Base Europe Pilot Plant unravels insights into SMARTBOX’s economic viability. 🌱 Watch Cedric’s Video SMARTBOX Project on LinkedIn: Techno-Economic Assessment as important tool for bio-based processes and…

📰 For More Details: Dive into our LinkedIn posts for additional information and behind-the-scenes insights. BBEPP https://www.linkedin.com/company/bio-base-europe/mycompany/ | BIOCON KU Leuven https://www.linkedin.com/company/biocon-kuleuven | ITQB Nova https://www.linkedin.com/school/itqbnova/

Embark on this Journey with SMARTBOX! Witness innovation, sustainability, and collaboration like never before. 🚀

December 2023

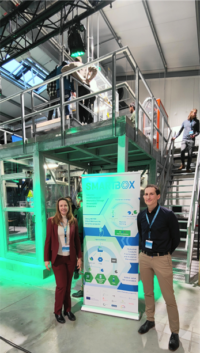

Biocon official opening event

🌟 Biocon Opening Event – December 2023

Celebrating Success!

🎉Congratulations to Biocon on their official opening event at the TRANSfarm location in Bierbeek on October 5, 2023. With a vibrant atmosphere and over 150 participants, the event marked a significant milestone.

👥 The Pilot Process Hall buzzed with excitement, welcoming participants from diverse backgrounds. For the official invitation, check here.

🔗 Representatives in Attendance: Rakesh Nair, Cedric Vander Cruyssen, and Tanja Meyer from Bio Base Europe Pilot Plant attended the event, adding their presence to the celebration.

📰 KU Leuven highlighted the event in a press release. Read more about the Biocon facility and its significant opening.

📖 Full Story: Dive into the complete Biocon story in English here or visit their official website here.

🌟 Follow us for more updates on groundbreaking events and achievements! 🌐🎊

December 2023

Succesful scale-up 150 l for vanillin + DSP

SMARTBOX Achieves Breakthrough in Vanillin Scale-Up: Pilot Scale Production at 150L

In a remarkable stride towards sustainable chemistry, SMARTBOX successfully executed the scale-up of vanillin production to a pilot scale of 150 liters at Bio Base Europe Pilot Plant. This accomplishment is a result of meticulous optimization processes and collaborative efforts by research partners and the scale-up facility.

🔬 Optimization and Strain Engineering:

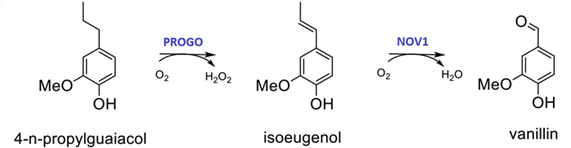

The journey began with the successful optimization of PROGO and NOV1 enzyme fermentation and production at BBEPP, utilizing innovative strains provided by our partners at RUG (NL) and ITQB (POR). The enzymes underwent rigorous lab-scale testing for the conversion of 4-n-propylguaicol into vanillin through a two-step reaction.

🚀 Pilot Scale Production:

Building on the triumph of laboratory optimization, the coupled PROGO – NOV1 fermentation was seamlessly executed at the 150L scale. The subsequent bioconversion, performed in one of the fermenters from the coupled process, utilized commercial propyl guaiacol (PG) as the feedstock.

⚗️ Conversion Success:

With precision, PG was introduced to the reactor at a concentration of 0.84 g/L, almost entirely converting and yielding 4 g/l of isoeugenol. The NOV1 enzyme then transformed this isoeugenol into vanillin, resulting in a final concentration of ~5 g/L. The process achieved a molar yield of 45.9% on the initial PG added.

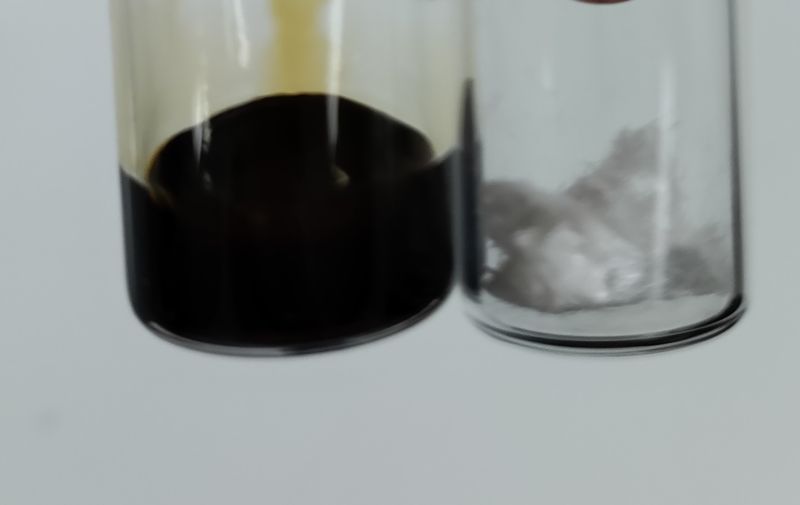

🌿 Purity Verification:

The downstream processing (DSP) steps of vanillin production included solvent extraction and crystallization, culminating in the formation of pure vanillin crystals. Rigorous purity testing conducted by industry partner Borregard using NMR, GC_FID, and HPLC-UV methods confirmed purity levels of 97.8%, 99.4%, and 98.6%, respectively.

📸 Visual Insights:

Explore the intricate process through images capturing the various stages (above), including a snapshot of the conversion process and a glimpse of the final vanillin crystals.

This achievement not only underscores the success of our collaborative efforts but also positions SMARTBOX at the forefront of sustainable biobased chemical production. Stay tuned for more groundbreaking updates on our journey towards a greener future! 💚 #SMARTBOXProject #VanillinScaleUp #SustainableChemistry #BioBaseEuropePilotPlant

November 2023

A One-Pot, Whole-Cell Biocatalysis Approach for Vanillin Production using Lignin Oil

Exciting News! In October 2023, the SMARTBOX Project achieved a groundbreaking method for vanillin production, steering away from the environmentally hazardous petroleum-derived phenol process.

🔄 Innovative Approach: Utilizing 4-n-propylguaiacol (4PG) from softwood lignin oil (RCF), offering an eco-friendly alternative.

👩🔬 Efficient Conversion: Engineered E. coli cells achieved a remarkable 66% vanillin yield from 4PG in RCF lignin oil, showcasing process efficiency.

📈 Scalability and Yields: Scalable strategy produced an unprecedented 18% and 3% vanillin yield from lignin oil and spruce wood, highlighting large-scale potential.

🌱 Sustainability Milestone: Bioconversion process demonstrates excellent tolerance at high material loadings, laying the groundwork for efficient biobased vanillin production using depolymerized lignin.

🌐 Read More: For in-depth insights, check out our publication (Read More).

see: https://onlinelibrary.wiley.com/doi/10.1002/adsc.202300868

📰 Further insights and discussions can be found on LinkedIn:

Ivana Maric’s post Ivana Maric on LinkedIn: #valorization #lignin #biocatalysis #sustainability #biotech #biocatalysis…

Thank you for supporting the SMARTBOX Project’s journey towards a sustainable future! 🌐🌟

October 2023

Publication in ACS Catalysis by Uni Pavia and RUG

Unlocking Bioeconomy Potential: One-Pot Biocatalytic Synthesis of rac-Syringaresinol from Lignin-Derived Phenol

Innovation Unveiled: Uni Pavia, RUG Collaboration

🔍 Circular Bioeconomy Drive: Embark on a journey through a one-pot biocatalytic cascade reaction, producing racemic syringaresinol—a versatile compound for nutraceutical and polymer chemistry applications.

🧪 Key Advances: Engineered eugenol oxidase catalyzes the oxidation of dihydrosinapyl alcohol into sinapyl alcohol with remarkable conversion and chemoselectivity. Insights into mutation influence are revealed through the crystal structure.

🔗 Immerse yourself in the comprehensive publication here.

One-Pot Biocatalytic Synthesis of rac-Syringaresinol from a Lignin-Derived Phenol

Follow Uni Pavia and RUG for continuous breakthroughs in biocatalytic pathways, creating valuable compounds from lignin. 🌿📰

#ACSCatalysisPublication #BiocatalyticInnovation #CircularBioeconomy

October 2023

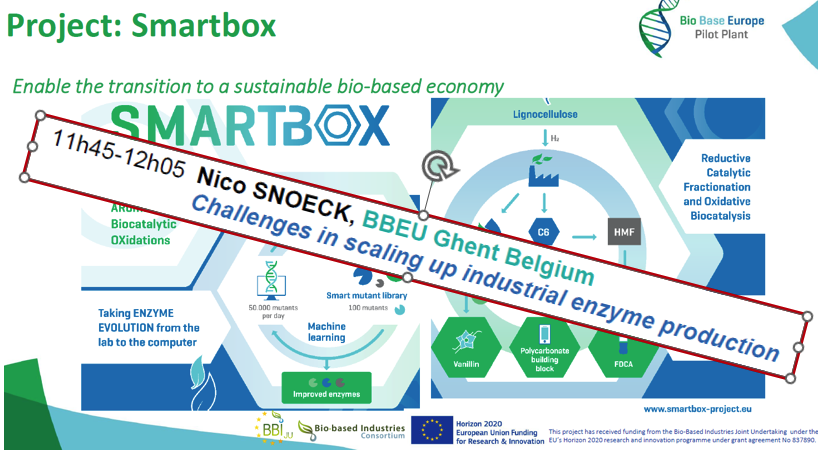

SMARTBOX Results at ENZYNOV’2 Conference – Paris – Presentation BBEPP

📅 Conference Spotlight – October 26-27, 2023

SMARTBOX proudly presented key results at the ENZYNOV’2 Conference – Enzymatic Biocatalysis For Industry in Paris. 🎉 The spotlight was on addressing challenges in scaling up industrial enzyme production.

🗣️ Nico Snoeck from Bio Base Europe Pilot Plant explained the “Challenges in scaling up industrial enzyme production” and shared insights into the enzymatic conversion of feedstock to bio-based FDCA, a vital chemical building block for PEF (Polyethylene Furanoate).

🔍 ENZYNOV’2 centered on utilizing enzymes and biocatalysis technologies for more sustainable industrial applications in various sectors, including chemistry, cosmetics, pharma, food, and detergents. Discussions included the state-of-the-art technology, major market drivers by sector, manufacturing challenges in large-scale enzyme production, and custom-designed enzymes. Disruptive innovations in the field were also explored.

For more details, explore conference presentations and delve into the advancements discussed. Learn More

October 2023

SMARTBOX Workshop at Pitch Perfect Event 2023

Partners pitched results at the Pitch Perfect Event

On the 25th September 2023 SMARTBOX partners had the honor to present SMARTBOX project results in Brussels within the fourth edition of the ‘Pitch Perfect and Boost the European Bioeconomy’ event at the Sheraton Brussels Airport Hotel.

In the morning and afternoon session on Emerging innovative technologies for the bioeconomy and New Investments and Developments in the EU Pilot and Demonstration scene SMARTBOX partners pitched proudly about their business and work achieved within the SMARTBOX Project and their further development of the bioeconomy.

B4Plastics Stefaan De Wildeman, CEO: “B4Plastics – Redesigning tomorrow’s plastics. TODAY“.

Bio Base Europe Pilot Plant Tanja Meyer, Project Acquisition Coordinator: “Development and scale-up of an enzymatic process fro FDCA synthesis from HMF”.

Zymvol Biomodeling Lur Alonso Cotchico: “Computationally tailor-made enzymes for industrial applications”.

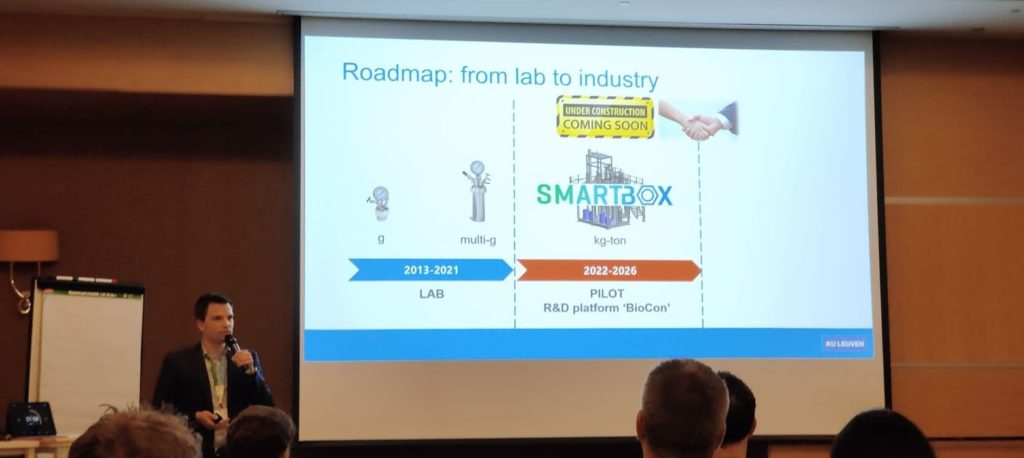

KU Leuven Sander Van den Bosch: “BioCon pilot facility for sustainable chemistry”.

September 2023

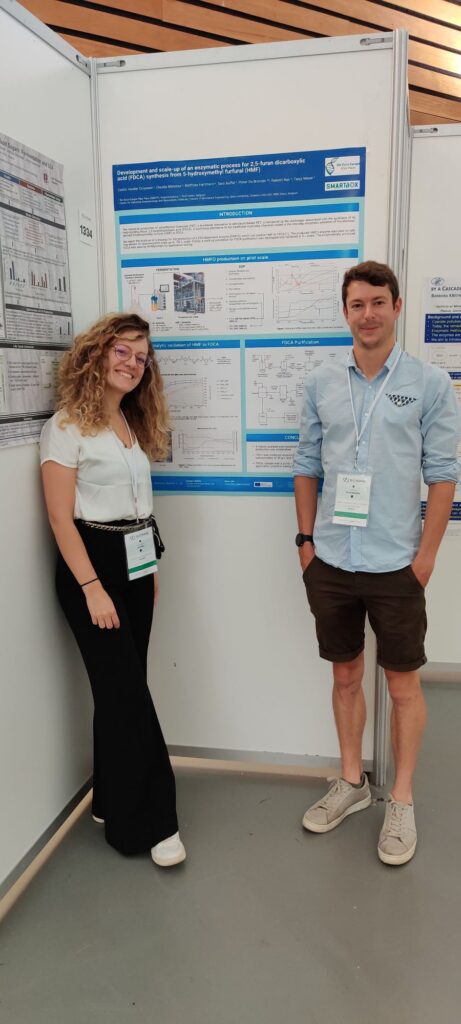

BBEPP at Biotrans 2023 Conference for biocatalysis upscaling – Poster Presentation

🎉 SMARTBOX showcased smart enzymes at Biotrans 2023, demonstrating seamless lab-to-pilot scale-up. The focus: converting biobased HMF to FDCA which has a large potential of application for green chemicals and biopolymers. More information on Biotrans 2023 here: Welcome — Biotrans 2023

Bio Base Europe Pilot Plant’s 2 phd students, presented groundbreaking results at the BioTrans Conference 2023 in La Rochelle, France. Actively contributing to enzyme production and biocatalysis, they excel in scale-up and process optimization. Bio Base Europe Pilot Plant is an active player within the field of enzyme production and biocatalysis for both scale-up and process optimisation.🌱🔬

SMARTBOX leads in sustainable biocatalysis, propelling towards safer and greener enzyme applications. 🚀 see all ongoing news:

SMARTBOX Project on LinkedIn: #enzymes #scaleup #pilot #biobased #greenchemicals #biopolymers…

June 2023

Publication in Royal Society of Chemistry by KU Leuven

Innovation Unveiled: KU Leuven Breakthrough

Royal Society of Chemistry publication in May 2023

🎉 Congratulations to KU Leuven on a Pioneering Achievement!

🔍 Revolutionizing Biorefinery Technology: Explore the cutting-edge lignin-first reductive catalytic fractionation (RCF) process, introducing a novel industrial-scale approach for a disruptive wood biorefinery.

🌍 Step away from purified solvents with a unique process enriching methanol with reaction by-products, slashing costs and CO2 footprint. The impact of liquor recycling % was scrutinized through a coupled techno-economic analysis (TEA) and life cycle assessment (LCA), revealing a potential lignin oil minimum selling price (MSP-RLO) as low as €1000 per ton.

🔗 Dive into the details of this groundbreaking process here.

Join KU Leuven on the path to sustainable lignocellulose biorefinery, where innovation meets efficiency. 🌿📰 #KULeuvenInnovation #WoodBiorefinery #SustainableTechnology

May 2023

ITQB attending NovelEnzymes2023 – Poster presentation

Meet Mario De Simone, a passionate Ph.D. student at ITQB-UNL, Mario presented his groundbreaking work at #NovelEnzymes2023 in Greifswald, Germany. 🌐 Connect with Mario

🚀 Mario shared insights into his collaborative work with the SMARTBOX Project, focusing on the engineering of NOV1 dioxygenase by identifying distal hotspots.

🗣️ Mario’s Experience: “Happy to have attended #NovelEnzymes2023 last week in Greifswald, Germany. It was a nice week full of interesting lectures and colleagues. Here I am presenting my poster on engineering of NOV1 dioxygenase, in collaboration with SMARTBOX Project.” View Mario’s Poster

April 2023

Top-Downloaded Author Recognition University of Pavia Andrea Mattevi

Congratulations Andrea!

Andrea Mattevi from UniPavia received outstanding acknowledgment as one of the top downloaded authors in March 2023. ” Among work published in an issue between 1 January 2021 – 31 December 2021, yours received some of the most downloads in the 12 months following online publication”

The paper in focus is part of the SMARTBOX Project https://chemistry-europe.onlinelibrary.wiley.com/journal/14397633

📈 Achievement Highlight: UniPavia proudly shared news about the manuscript titled “Discovery, Biocatalytic Exploration and Structural Analysis of a 4-Ethylphenol Oxidase from Gulosibacter chungangensis.” The paper, a collaborative effort with RUG, was published as a contribution to the ChemBioChem special issue Biotrans2021.

Celebrating Academic Excellence: UniPavia and Andrea Mattevi, thank you for contributing to the SMARTBOX Project’s success. We look forward to more groundbreaking work in the future! 🎓🔍

March 2023

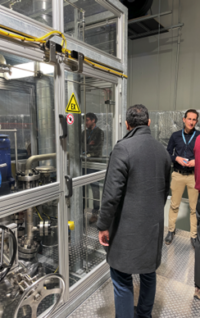

🌟 Major Milestone at TRANSfarm KU Leuven – Pilot reactor arrived

🎊 Celebrating Progress! February marked a significant achievement for Biocon! The pilot reactor arrived at TRANSfarm KU Leuven, marking a substantial step forward in the field of sustainable chemistry.

🚀 As a cutting-edge KU Leuven scale-up facility, Biocon is dedicated to sustainable chemistry. The arrival of the pilot reactor is a crucial step towards transforming plant biomass into liquid bioaromatics and 2G sugar (polymers).

Join the Celebration! Let’s celebrate this big moment for Biocon! Check out the LinkedIn post for a closer look and join us in commemorating this accomplishment. 🙌

🌐 Curious to know more? Be part of this groundbreaking venture by following Biocon on LinkedIn, and stay tuned for upcoming announcements! 🌿🚀

February 2023

Exploring KUL – BIOCON: A Cinematic Journey 🌟

Engaging Insight – January marked the release of an insightful movie on KUL – BIOCON!

🎬 For an in-depth look, watch the captivating video here. Discover Biocon’s feedstocks, products, installation, team, future plans, and financial support in a nutshell.

🌐 Stay Tuned for More:

For regular updates and a continuous exploration of Biocon’s transformative journey, subscribe to the Biocon channel. Stay connected with the latest developments and exciting announcements! 🌿🎥 https://www.linkedin.com/feed/update/urn:li:activity:7150090530738118657/

#KULBIOCONMovie #BioconChannel #SustainableInnovation

January 2023

Publication in Nature Publication by Uni Pavia, RUG and Zymvol

Breaking Ground – November 2022 marked the publication of a collaborative work in Nature!

Congratulations to the esteemed teams at Uni Pavia, RUG, and Zumvol for the remarkable achievement of having their research featured in the prestigious publication of Nature!

🔍 “Structure- and computational-aided engineering of an oxidase to produce isoeugenol from a lignin-derived compound”: Explore how 4-alkylphenols from lignocellulosic biomass are transformed into valuable isoeugenol. Witness the engineering of a bacterial eugenol oxidase into a tailored biocatalyst for lignin-based monophenols.

🔗 For an in-depth understanding, delve into the detailed publication here.

🌐 Stay tuned for more groundbreaking research and collaborative efforts. Follow the advancements of Uni Pavia, RUG, and Zymvol for regular updates on their innovative journey! 🌿📰 #NaturePublication #Biocatalysis #ResearchInnovation

November 2022

8th project meeting, Lausanne, Switzerland 🏔️

Exciting updates from our 8th project meeting in Lausanne, Switzerland! In October 2022, partners converged to discuss a crucial development: a proposal for a live WP7 meeting with key partners. This aims to finalize project details, gather data, and plan the final steps.

⏰ Timing is crucial, and we’re carefully considering the optimal moment, contingent on progress in all value chains. Factors such as potential linkage with a broader project meeting and the approval of an extension may influence scheduling.

Your unwavering dedication and collaborative spirit continue to propel the SMARTBOX Project toward success. Thank you for your ongoing commitment! 🌿🔗

October 2022

Check out our latest work on engineering NOV1, a dioxygenase able to oxidase lignin-derived monomers🌱

The Smartbox team would like to share the latest collaborative paper toward a zero-waste, bio-based society by engineering an enzyme to improve the conversion yields of lignin-derived isoeugenol to vanillin. Thanks to Mario De Simone and Andrea Mattevi, Laura Alvigini from Pavia Univ, and collaboration with Lur Alonso Cotchico, Zymvol Biomodeling SL

Title: Rationally Guided Improvement of NOV1 Dioxygenase for the Conversion of Lignin-Derived Isoeugenol to Vanillin

Direct Link: https://pubs.acs.org/doi/10.1021/acs.biochem.2c00168

June 2022

7th project meeting, Oeiras, Portugal

🎉 Our 7th project meeting in Oeiras, Portugal, in April 2022, was a resounding success! Partners from 8 European countries engaged in fruitful discussions, fostering an inspiring exchange of ideas.

🌱 Dedicated to advancing sustainable solutions for lignin valorization, we remain committed to the United Nations Sustainable Development Goals.

Gratitude to our hosts, the ITQB Team, for creating a welcoming atmosphere in beautiful Oeiras. Special thanks to all participants for contributing to the success of this event.

Thank you for your continued dedication to the SMARTBOX Project! 🌿🌐

April 2022

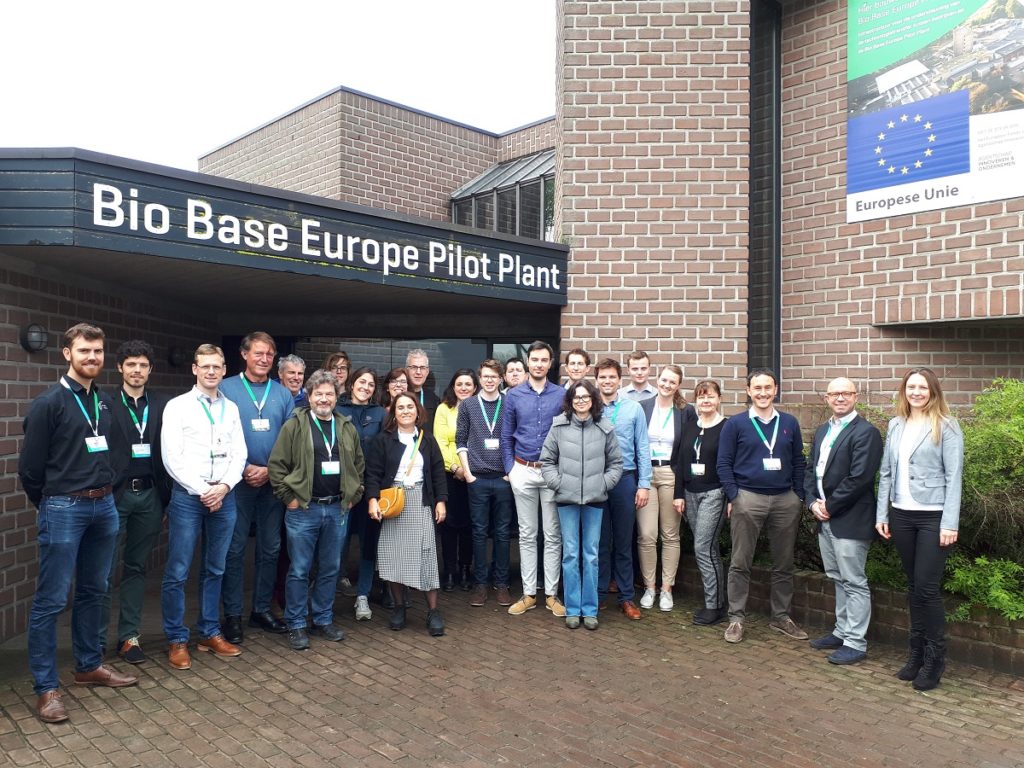

Hybrid project meeting in 2021 – 6th project meeting

🎉 It has been great getting together again with all the SMARTBOX Project partners for the 6th project meeting in a hybrid manner in the second week of November (08.-09. Nov 2021) organised at the Bio Base Europe Pilot Plant in Ghent, Belgium

🌱 At SMARTBOX Project we’re all participants from 8 European countries working together on sustainable ways to valorize #lignin, and thus contributing to the Sustainable Development Goals of the United Nations.

How do we do this?

✔️ Applying computational enzyme engineering

✔️ Creating added-value bio-aromatics

✔️ Setting-up a lignin-first biorefinery at pilot-scale

November 2021

SMARTBOX presents at WoodZymes Final workshop

BBI JU funded project SMARTBOX and others will present the approach they are following to achieve full exploitation of lignocellulose biomass.

The final event of the WoodZymes project will be held online on November 4th 2021 to present the main achievements and conclusions attained towards full exploitation of lignocellulose. It will also count with participation of UNRAVEL and SMARTBOX, two related BBI JU funded projects dealing with plant biomass valorisation.

The WoodZymes project, a Research & Innovation Action funded by the Bio-Based Industries Joint Undertaken (BBI JU), will conclude next November after three and half years of collaboration between eleven European institutions and companies coordinated from the Centre for Biological Research Margarita Salas (CIB) of the Spanish National Research Council (CSIC). In a final online event to be held on November, 4th, the main achievements and conclusions attained in the project will be shown, together with an overview of two related BBI JU funded projects (UNRAVEL and SMARTBOX) dealing with valorisation of lignocellulose components by different approaches. A general outlook of the overall achievements and perspectives of the BBI JU initiative will be also presented.

The feasibility of this ambitious project has been based on the collaborative work of a strong European consortium from Portugal, France, Finland and Spain, formed by world-leading companies of the sectors of pulp & paper (The Navigator Company and Fibre Excellence), fibreboard manufacture (FINSA France) and insulation materials (Soprema), a biotech SME commercializing enzymes for biomass conversion (MetGen) and several research institutes (CIB, IRNAS and IATA from CSIC) and technology centres (RAIZ, CTP and FCBA) of the wood, cellulose, lignin and enzyme sectors.

This online webinar has been organized by WoodZymes partner FCBA in collaboration with the Coordination Team from CIB-CSIC.

Link to download the workshop program: Woodzymes final workshop progam 4 Nov 2021.pdf

October 2021

Publication in ChemBioChem by partner Uni Pavia and Uni Groningen

The manuscript ”Discovery, biocatalytic exploration and structural analysis of a 4-ethylphenol oxidase from Gulosibacter chungangensis” displayes the joint work of University of Pavia and University of Groningen within the Smartbox activities.

Congratulation to the contributors: Alvigini Laura, Alejandro Gran-Scheuch, Yiming Guo, Milos Trajkovic, Mohammad Saifuddin, Marco W Fraaije, Andrea Mattevi

The paper has been published as a contribution to the ChemBioChem special issue Biotrans2021.

Link: https://chemistry-europe.onlinelibrary.wiley.com/doi/abs/10.1002/cbic.202100457

October 2021

Partners pitched results at the Pitch Perfect Event

The first physical meeting again after 2 years with almost half of the partners thanks to the “Pitch Perfect and Boost the European Bioeconomy 2021” event that took place in Brussels last week. There we welcomed BBEPP, KU Leuven, B4Plastics and Zymvol flying in from Spain!

The overall goal of Smartbox was presented in the introduction part in the morning session in front of an audience of 170 participants coming from all over Europe!

In the afternoon session 3 of our partners pitched proudly about their business and work achieved within the SMARTBOX Project and their further development of the bioeconomy.

B4Plastics, Belgium, Sil Nevejans: “B4Plastics – Redesigning tomorrow’s plastics. Today.“

Zymvol Biomodeling SL, Spain, Lur Alonso Cotchico: “In Silico Engineering of Oxidative Enzymes Applied to Lignin Revalorization Processes”

KU Leuven, Belgium, Joost Van Aelst: “BioCon pilot platform – upscaling lignin-first biorefinery”

SMARTBOX Project was one of the co-organisers of joint pitching, matchmaking, and networking event: “Pitch Perfect and Boost the European Bioeconomy 2021”, held in Brussels on September 28th, 2021 from 10am-5pm. This event brought together the networks of six important bioeconomy platforms: Pilots4U, Tech4Biowaste, BioeconomyVentures, Smartbox, Waste2Func and Bio Base Connect.

September 2021

”Sharper night” in Pavia

Researchers from different fields speak about a scientific topic of interest to a mixed audience.

Smartbox was presented by Laura Alvigni from University of Pavia with a live presentation in Pavia on 24th October 2021. Laura presented in general about what SMARTBOX is, what its impact is and what University of Pavia and her work field are in the laboratory. Below a picture of her on stage:

Link to the event (in Italian): https://www.sharper-night.it/evento/argomenti-scientifici/

September 2021

Co-organisation of the Pitch Perfect and Boost the European Bioeconomy 2021 in Brussels

SMARTBOX Project will be one of the co-organisers of the proudly presented joint pitching, matchmaking, and networking event: “Pitch Perfect and Boost the European Bioeconomy 2021”, to be held in Brussels on September 28th, 2021 from 10 am – 5 pm.

This event brings together the networks of six important bioeconomy platforms: Pilots4U, Tech4Biowaste, BioeconomyVentures, Smartbox, Waste2Func and Bio Base Connect. As such, we can guarantee a diverse attendance reaching from investors, SMEs, start-ups, scale-ups, large companies, research organisations, technology providers to organisations offering relevant innovation services such as access to finance, scale-up trials, application testing, business plan writing, feedstock analysis, life cycle assessment, social acceptance, etc.

Participants are invited to submit a pitch application for a 6 minutes pitch. As we are organising 6 pitch sessions of 90 minutes each, we are looking for at least 66 inspiring pitches. Not to exclude any interesting developments, pitch categories are not defined upon registration but should be relevant for further development of the bioeconomy.

The matchmaking are one-on-one meetings of 15 minutes aimed at finding new partners. The scheduling of these meetings will be supported by an online matchmaking system, easy to use on a smartphone or laptop.

More information and registration: Pitch Perfect and Boost the European Bioeconomy 2021 | Pilots4U

August 2021

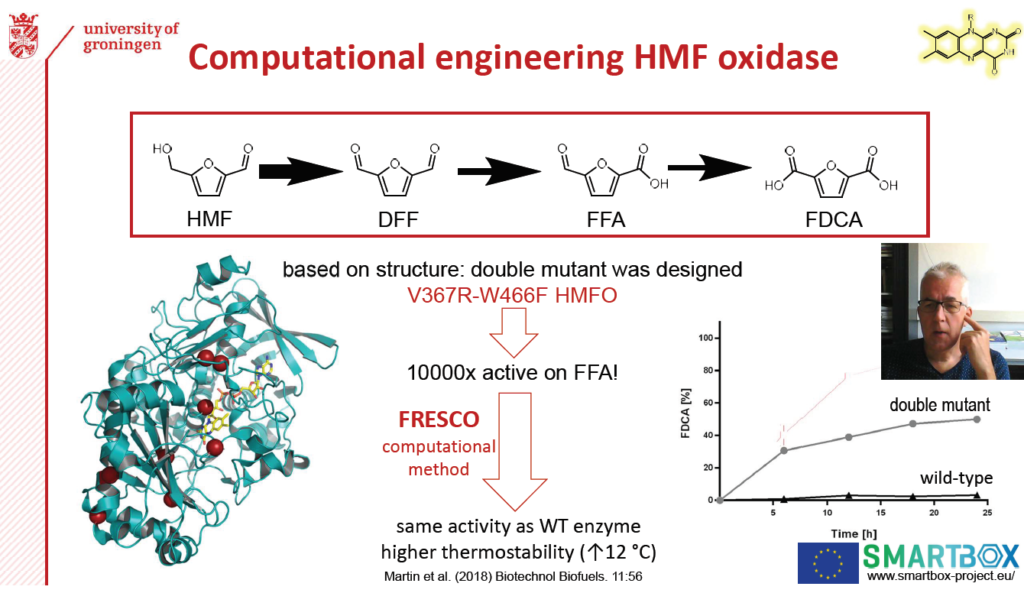

Partner Rijksuniversiteit Groningen at Biotrans 2021 Graz conference

Marco Fraaije University Professor at Groningen (RUG) spoke at the Biotrans 2021 Graz conference, where he presented some results on the computational engineering of HMF oxidase which are in the focus of the SMARTBOX Project.

Prof. Fraaije was also interviewed in the course of the conference for a podcast.

EPISODE 8: Listen to Marco Fraaije’s episode on “In the Active Site”

August 2021

KU Leuven and MTSA Technopower finalising detailed design

We are proud to communicate that, following a public procurement procedure, KU Leuven has started, in January 2021, a collaboration with MTSA Technopower for the detailed design and construction of a prototype lignin-first biorefinery pilot-scale installation.

Currently, the detailed design documents of the pilot are undergoing final revisions. Procurement has started, followed by construction and factory acceptance testing, all in 2021. The installation is planned to become operational in the first quarter of 2022 and will be hosted at TRANSfarm, a KU Leuven core facility that supports research groups to scale up their lab expertise to pilot scale in the broad area of circular bio-economy (https://set.kuleuven.be/over-ons/groepsdiensten-en-faciliteiten/transfarm).

Full information: Lignin-first biorefinery at pilot-scale: KULeuven and MTSA Technopower finalising detailed design

June 2021

KU Leuven RCF technology presented in CIC2021 Event Serie III

KU Leuven presents: “Lignocellulose biomass as sustainable resource: upscaling of the reductive catalytic fractionation technology” where also SMARTBOX activities are part of.

May 27th 1-4 pm

Registration on LinkedIn

May 2021

General Project Video available

Enjoy the journey and discover on the way products in the supermarket, problems with fossil fuel, “lignin mortar”, the three pillars of the project, and some technical background to the terms of “Reductive Catalytic Fractionation” , “oxidative biocatalysis” and the advantages of a handy enzyme toolbox.

What will be inside your box? – Fill it up with sustainable and bio-based products

May 2021

2 years of work collaboration – 5th Project meeting

Life is beautiful not because of the things we see or do.

Life is beautiful because of the people we meet.

– Simon Sinek

SMARTBOX people have met to our 5th project meeting online in the last week of April 2021.

A lot of information on the progress has been shared. Partners not only shared their newest progress on enzyme developments, identified new mutants, simulations and fermentation runs. There were some vivid discussions on publications, patents and innovation pathways within partners from academia and industrial end-users.

Beautiful was also our social lunch activity, when we discovered together each other’s preferences on chocolates, wines and landscapes within the wonderroom tool.

April 2021

Publication on RCF of pine wood by partner KUL

Partner KUL publishes an article with the title “Reductive catalytic fractionation of pine wood: elucidating and quantifying the molecular structures in the lignin oil. ”

Published in Royal Society of Chemistry, Chemical Science; 2020; Vol. 11; iss. 42; pp. 11498 – 11508

Abstract:

In-depth structural analysis of biorefined lignin is imperative to understand its physicochemical properties, essential for its efficient valorization to renewable materials and chemicals. Up to now, research on Reductive Catalytic Fractionation (RCF) of lignocellulose biomass, an emerging biorefinery technology, has strongly focused on the formation, separation and quantitative analysis of the abundant ligninderived phenolic monomers. However, detailed structural information on the linkages in RCF lignin oligomers, constituting up to 50 wt% of RCF lignin, and their quantification, is currently lacking. This study discloses new detailed insights into the pine wood RCF lignin oil’s molecular structure through the combination of fractionation and systematic analysis, resulting in the first assignment of the major RCFderived structural units in the 1H–13C HSQC NMR spectrum of the RCF oligomers. Specifically, b-5 g-OH, b-5 ethyl, b-1 g-OH, b-1 ethyl, b-b 2x g-OH, b-b THF, and 5-5 inter-unit linkages were assigned unambiguously, resulting in the quantification of over 80% of the lignin inter-unit linkages and end-units.

Detailed inspection of the native lignin inter-unit linkages and their conversion reveals the occurring hydrogenolysis chemistry and the unambiguous proof of absence of lignin fragment condensation during proper RCF processing. Overall, the study offers an advanced analytical toolbox for future RCF lignin conversion and lignin structural analysis research, and valuable insights for lignin oil valorization purposes.

Please find more information on Limo LIBISnet Infopage

March 2021

Publication on overcoming scale-up hurdles for the RCF of lignocellulose biomass

Partner KUL publishes an article with the title “Perspective on Overcoming Scale-Up Hurdles for the Reductive Catalytic Fractionation of Lignocellulose Biomass.”

Published in Industrial & Engineering Chemistry Research; 2020; Vol. 59; iss. 39; pp. 17035 – 17045

Abstract:

In the last five years, reductive catalytic fractionation of lignocellulose biomass has emerged as a promising biorefinery concept that combines biomass fractionation with the preservation of chemical functionality in its products. Although significant efforts have been made in optimizing this technology on lab scale, the implementation on a larger (pilot) scale is still in its infancy. In our own search for the scale-up potential of this technology, we faced several fundamental and technical research questions that, to this day, remain unanswered. These fundamental questions are related to four main aspects of RCF, the lignocellulose feedstock, the operating pressure, the redox catalyst and the solvent. In order to inspire future multidisciplinary research in the RCF community, these scale-up challenges are presented and discussed via multiple angles combining chemical process hurdles with more technical aspects, such as reactor design and process consequences.

Please find more information on Limo LIBISnet Infopage

March 2021

18 month work implementation is paying off

In our mid-term review we received congrats on the progress by our BBI JU project officer Ana Ruiz for the work that has been done during the first 18 month, despite some delays caused by lab lockdowns across Europe and travel restrictions

Unfortunate this meeting had to happen online due to the ongoing travel restrictions, but nevertheless we spend a pleasant day discussing and showing for hours the work implementation to the EC and the evaluators.

SMARTBOX main project impacts during its first 18 month concluded in

- Engineered highly robust strains and there is continuous development for further improvement

- Successful technology transfer and pilot production of the enzyme and conversion at TRL 5

- Successful conversion of HMF to FDCA

- Successful implementation of the Fresco computation tool to design thermostable proteins

- Basic Design phase and tender for detailed engineering and construction of the mini pilot reactor set up

- Implementation of goal and scope definition of the TEA and LCA

- All deliverables and milestones were achieved with minor delays, fulfilling the project objectives

Let’s enter the 2nd stage to develop biobased fusion technology pathways from enzyme engineering over biotech to end user application.

February 2021

Virtual Partner meeting for 18 month joint collaboration

Even some new non-technical worldwide challenges had to be overcomed in the last couple of month, SMARTBOX is still on a good way to find sustainable ways to valorize lignin. As presented during the 4th Project Meeting (17/11/2020) that took place this week, all partners shared enthusiastically their latest advances and progresses they made.

Partner commented that it was gratifying to see the chain from enzyme engineering to a product seems to be successful for the HMF>FDCA reaction.

Yes, we believe in its potential!

Never stop the conversation and underestimate the team spirit working towards the same Sustainable Development Goals by enabling bio based chains for new innovations within the bio economy.

SMARTBOX also welcomed some new faces that joined recently and will become quickly integrated into the SMARTBOX Family and its Spirit.

The 3rd progress meeting in online form!

Meeting face-to-face in corona times? Why not?

We held our progress meeting over 2 half days (18.-19. May) online and it was a complete success. Our time was used very efficiently and not only we managed only little technical hurdles together, but even we shared some good real laughs.

The core topics on the agenda were the progress in computational enzyme engineering, process development and in reductive catalytic fractionation. Computational enzyme engineering was presented by Zymvol, University of Groningen, ITQB and Uni Pavia. The process development progress in the production of the first product, FDCA, was reported by BBEPP with promising results. KU Leuven presented the current results of RCF and the optimization as well as scale up thereof.

Although we were all efficient and satisfied with the exchange on the technical work, we are also looking forward to deepening our talks again face-to-face in person. Hopefully for the next meeting. In the meantime the SMARTBOX Team wishes that you all stay safe and healthy!

Italian Uni Pavia welcomes partner for the 2nd project meeting

In the wonderful city of Pavia, 35 km south of Milan, a comune in the south-western Lombardy in northern Italy, the partner University of Pavia welcomed to the 2nd project meeting on a sunny day Thursday 17/10/2019 for a two day meeting.

On the agenda especially the progress towards the platform development was discussed. Represented by University of Groningen, Zymvol, ITQB and Uni Pavia itself. Technology Transfer and Process Optimisation towards FDCA has been presented by BBEPP. The work implementation towards process development for the intermediates through RCF has been shown by KU Leuven. First consideration on life-cycle-assesment for the processes were not to be missed and presented by Quantis.

Greentech pioneer AVA Biochem teams-up with Michelin Group to foster eco-innovation

AVA Biochem AG in Zug, Switzerland has developed, patented and piloted a fully water-based process for the conversion of industrial sugars into the 100% bio-based molecule 5-HMF. This platform chemical is ideally positioned to replace petroleum-sourced chemicals in various mass-market applications, due to its versatility, non-toxicity and bio-sourcing. Applications include biopolymers (such as yarns, films, bottles and other packaging) as well as resins and adhesives, where 5-HMF replaces highly toxic formaldehyde.

With the common goal to further implement 5-HMF in various materials and chemical applications, AVA Biochem has entered into a Joint Development Agreement with the Michelin Group.

Please find more information in AVA Biochem’s full press release (31/01/2020).

Partner ZYMVOL receives 1,3 M€ from EC for an SME Instrument Grant

ZYMVOL Biomodeling S.L has been awarded with 1,3M€ from European Commission H2020 program SME Phase2, to develop the project, “UNLOCK-EDD: UNLOCK next generation computer guided Enzyme Discovery & Design”, focused on continuing technological improvement, development of a new pipeline for enzyme kits and starting the development of proprietary enzyme production.

ZYMVOL Biomodeling SL is a privately funded company specialized in in silico enzyme engineering. Founded in May 2017, the company currently has customers in Chemical, Pharmaceutical, Food and Biotech sectors and is actively engaged in highly innovative and competitive R&D activities.

Check the full press release here: Full press release

More info about ZYMVOL: www.zymvol.com

SMARTBOX kick-off activites for the next 4 years

Glad to receive our partners for our brand new BBI Project SMARTBOX at the coordinators facility Bio Base Europe Pilot Plant in Ghent.

On the 9.-10. May 2019 all 11 partners met to kick-off the activities for SMARTBOX.

SMARTBOX stands for Selective Modifications of ARomatics through Biocatalytic Oxidation.

Our joint goal is to make breaktrough developments for oxidative enzymes. Although they have the potential to improve the economic and environmental sustainability of biorefineries, they have not experienced a complete come out yet in the biobased industries.

Keep in touch to stay informed in our LinkedIn Group: Click here